What is an extruder used for?

- 1、Aug 26, 2010 - The most common cereals used on a daily basis for making breakfast cereal and snack foods are described below. Corn. Extruded snacks and

- 2、Double barrel extruders are primarily use for compounding in line of basic plastics with different plasticizers, fillers, colorants and other ingredients. Extrusion lends

- 3、Single-screw extruders are widely used for extruding film, sheet, and other applications that use pre-compounded pellets. The Buss Kneader is a special type of

- 4、Extruders were originally developed for extrusion of cereal grains and pet foods, but were later used to process other materials such as rice bran prior to solvent

- 5、May 7, 2017 - For this type of work, the most common is to use extruders with a compact size. The reason are very simple, smaller it is, easier to use it and so

- 6、Feb 14, 2018 - What is plastic extrusion? In a basic technical definition, it is the transformation of solid plastic mass converted into a shape that can be used as

- 7、Well, that defines Extrusion: a process used to create objects of a fixed cross-sectional profile. Commonly extruded materials include metals, polymers, ceramics,

- 8、Extrusion systems normally use both single and twin screw extruders. Single ... Single screw extruder is known as the most important type of extruder used in the

- 9、Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed through a die of the desired cross-section. The two main

- 10、Feb 14, 2017 - Extrusion is a process used for creating a product (an extrudate) by forcing a material through a die or an orifice to form a shape, or alternatively

- 11、Oct 28, 2019 - Single screw extruders are primarily used for melting and conveying polymers to extrude them into continuous shapes whereas twin screw

- 12、The machine used for extrusion is not surprising called an extruder. ... In the blown film process, the extruder or extruders melt plastic pellets and pump the hot,

- 13、Extrusion techniques can be used to process most thermoplastics and some thermoset plastics. The resins most commonly extruded for medical applications

- 14、is used for processing most types of thermoplastics and rubbers. The extrusion process is a simple process in which molten polymer is forced through a shaped die

Does an extruder cook food?

- 1、Extrusion is a low-moisture process that does not produce ... During extrusion cooking of starch-based foods, added water causes the starch.

- 2、by OO Adeleye · 2020 · Cited by 4 — High-temperature short-time extrusion cooking holds promise for the expanded use of non-conventional ingredients as food/feed due to its ...

- 3、The extent to which it does so is known as the expansion ratio. The extrudate is cut to the desired length by blades at the output of the extruder, which rotate ...

- 4、Apr 20, 2015 — a day's consumers do choice for nutritionally rich, therapeutic benefits and for ... Extrusion cooking of high moisture protein foods.

- 5、extrusion cooking. [ek′strü·zhən ‚ku̇k·iŋ]. (food engineering). The process by which moistened, expansile materials are plasticized in a tube by combination ...

- 6、Extrusion cooking involves the higher temperature and shorter time and collates thermal and mechanical shear forces for processing of food. Foods that are ...

- 7、Extruders can be thought of as high temperature short time cooking (HTST) equipment, that can transform various raw ingredients by forcing through a die to ...

- 8、Food products manufactured by extrusion usually have a high starch content such as pasta, breakfast cereals and ready-to-eat snack foods. Other food products ...

- 9、Extruders are widely used to cook, form mix, texturize and shape food ... to which it does so is known as the expansion ratio.

- 10、by D Dey · 2021 · Cited by 8 — This is because extrusion combines the simultaneous application of unit operations, such as mixing, kneading, cooking, and forming under high ...

- 11、by S Choton · 2020 · Cited by 8 — Extrusion cooking is mostly preferred, as it has high productivity and ... Now a day's consumers do choice for convenient ready to.7 pages

- 12、by M Mitrus · 2017 · Cited by 14 — Wheat, corn and potato starch were extrusion-cooked with different ... become a widely used method of processing in the agri-food industry, ...

- 13、This kibble is cooked in an extruder at temperatures between 170-180 degrees Fahrenheit for 55 seconds to 1 minute 45 seconds.

- 14、Dec 4, 2018 — Controlling the complex process parameters of extrusion cooking is the ... Treats from the 2018 TAMU Feed and Pet Food Extrusion Course.

Are all cereals extruded?

- 1、Introduction: Over the years, with increasing consciousness about the healthy food diets, demand for extruded cereals has been escalated. Extruded cereals are ...

- 2、The extrusion process making breakfast cereal and the difference from steel cut oats.

- 3、... for example, pasta and breakfast cereal. Extrusion involves changing the texture of the flour under pressure, usually at a temperature of over 100 C°, ...

- 4、Oct 9, 2019 — We invite you to the Next Seminar!! Don´t Miss it!! by All Extruded. PROFILE OF Wenger Manufacturing, Inc.

- 5、by A Borah · 2015 · Cited by 11 — Abstract. The low-amylose rice flour incorporated with seeded banana powder was extruded to prepare ready to eat breakfast cereals in a single-screw.

- 6、by D Torrallardona · 2012 · Cited by 8 — Abstract. Two trials were conducted to evaluate the effect of different cereals in piglet diets on the jejunal mucosa and the ileal and ...

- 7、Cereal-based snack foods cover a wide range of ready-to-eat products, such as popcorn, pretzels, breakfast cereals, and expanded products. The structure and ...

- 8、Sep 3, 2014 — A typical American breakfast consists of a bowl of cold cereal, which is made by a process called extrusion. An extruder is an industrial ...

- 9、Obviously whole grains are better, but are these puffed versions as bad as extruded boxed cereals? If anyone has come across any research on ...

- 10、It also discusses physicochemical changes in the different ingredient components as they are processed in an extruder, modeling and control of extrusion process ...

- 11、by GI Okafor · Cited by 25 — breakfast cereals (Okafor & Usman, 2013). It is envisaged that careful combination of these important food sources followed by extrusion and baking, ...

- 12、What are breakfast cereals made of? — This technology is used to develop breakfast cereal, extruded snacks, cereal based ingredients and several other ...

- 13、Oct 29, 2020 — Ready-to-eat breakfast cereals are typically made through the processes of flaking, puffing, or extrusion. (1) Generally speaking, the ...

- 14、A wide range of cereals can be used for the extruded mass itself, ... and shape of the final product, which could be a breakfast cereal or a savory snack.

What does a corn extruder do?

- 1、Common Direct Expanded products are Corn Curls, Corn cylinder (Collet as it is commonly called), ... The extruded crisp bread can be produced to.

- 2、The twin screw food extrusion equipment can be used as kneading blocks or to ... Corn snacks and breakfast cereals which have been extruded are becoming ...

- 3、Girish M. Ganjyal · 2020 · Technology & EngineeringCorn ingredients utilized in extrusion applications can be found in the form of corn grit, cornmeal, corn flour, or corn starch with variations in their ...

- 4、May 24, 2010 — Gobs of cornmeal are fed into an extruder , which rubs the meal between two metal plates. The friction melts the starch in the corn and ...

- 5、The extruder discs are printed on demand item. When your order comes in, it will be placed in the print queue and processed in that order. If you need these ...

- 6、Apr 6, 2021 — These methods form and transfer masa in to shapes that are then toasted or fried. Extrusion. Corn Chips Extruder Extrusion is where corn masa is ...

- 7、Nov 13, 2019 — Of particular note in corn snacks is the continued growth BFY Brands ... where one extruder can capably run multiple products with simple ...

- 8、Sep 5, 2017 — Examples include corn puffs, veggie straw snacks, pork rinds, ... Mintel predicts sales of salty snacks will reach $13.6 billion by 2021.

- 9、Food extruders can be visualized as a high temperature short time (HTST) device ... Some examples are corn curls, onion rings, three dimensional snacks and ...

- 10、We do not add any of the following which are found in many popular National Brands. Corn- Is an economical energy source, it can be hard to digest and a culprit ...

- 11、can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruel nutrient-flour, and baby food and so on. 5 corn Snack food extruder ...

- 12、Aug 26, 2010 — Similarly, twin screw extruders can handle fine as well as coarse granulation corn flour, while collet extruders require coarse granulation.

- 13、Extrusion processing can lead to an array of whole-grain products. ... alternative to traditional processing of corn, wheat, rice or bran into flakes.

- 14、Why You Need Soybean/Corn Extruder Machine. Soybean is one of the most nutritious foods, providing rich protein and amino acids, but they can't be directly ...

What is rice extrusion?

- 1、Yifex Extrusion: Turning broken rice into high-quality reconstituted rice. Processing broken rice into grains of rice with specific product characteristics ...

- 2、Jul 5, 2019 — Dry extrusion is to directly feed the rice bran from the rice production line into a dry extruder to puff it. Wet puffing is to inject a small ...

- 3、by Y Gat · 2015 · Cited by 37 — The choice of rice as a raw material for extrusion processing is due to its bland taste, its low protein content that could limit the non- ...

- 4、Sep 3, 2015 — The RICE EXTRUSION RIG (HDP/RE) allows the determination of rice kernel resistance to extrusion after cooking according to ISO 11747.

- 5、This article reviews research results of the many approaches to the formation of fortified rice analogues by extrusion‐based technologies.

- 6、In India, rice is forti ed using extrusion technology. In this technology, milled rice is pulverized and mixed with a premix containing vitamins and minerals.

- 7、Feb 21, 2013 — For the first time, growers, processors and food manufacturers can objectively and accurately analyse the resistance to extrusion of rice ...

- 8、Restructured rice can be done with several techniques, such as using extrusion. This study aimed to investigate the effect water content (35%, 37.5%,. 40%, 42.5 ...

- 9、by RJ González · Cited by 29 — Extrusion cooking allows obtaining precooked cereal products and a wide range of ready-to-eat foods. Two rice varieties having different amylose content ...

- 10、Jan 14, 2013 — A new extrusion process creates more nutritious puffed rice. Researchers at Cornell University's Institute of Food Science have engineered a ...

- 11、The processing line not merely can create instant rice powder for baby,but also make other extruded snacks,such as puffed snacks,core filling snacks and so ...

- 12、... in canine nutrition, and the effects of extrusion on protein quality. ... In the study, Hsu compared three starch sources: green banana flour, rice ...

- 13、Extruded Rice Products. Conclusion. Rice product produced by extrusion has the potential to diversify Guyana's economy. Key to the success of the.

- 14、by C Sitakalin · 2000 · Cited by 61 — Instrumental extrusion and compression tests have been successfully used in assessing cooked rice texture attributes. Extrusion tests are normally performed ...

How many types of extruders are there?

- 1、Jun 28, 2015 — This flexibility in Pin Type Cold Feed Extruders endears to all making it a universal extruder for many rubber compound formulations ...

- 2、The different 3D printing technologies that require an extruder ... Different systems actually exist, there is usually a combination of gears and hobbed ...

- 3、Learn more about how extruded rubber products are made. ... many extruded parts require plus or minus tolerances on their cross sections.

- 4、Advantages of Rubber Extrusion. There are different rubber processing methods but of all the methods, extrusion remains a popular choice for many manufacturers.

- 5、by C Rauwendaal · Cited by 1757 — Many different materials are formed through an extrusion process: metals, clays, ... There are two basic types of extruders: continuous and discontinuous or ...

- 6、Sep 29, 2017 — There are two different types of counter-rotating extruders. A parallel twin-screw extruder has two parallel screws that are the same ...

- 7、There are two types of extruders that are used in the 3D printing industry. ... Hot ends come in many forms but the standard ones consist of a feed tube, ...

- 8、Co-rotating, intermeshing TSEs utilize a modular design for barrels and screws. By sequencing barrel modules and screw elements for different process tasks ( ...

- 9、Aug 16, 2010 — TYPES OF EXTRUDERS. “Extruder” is the equipment which carries out the process of extrusion. Depending on the mechanism, by which the rubber ...

- 10、Single Screw Extruder; Twin or Multiple Screw Extruder; Ram Extruder. Single screw extruders and twin screw extuders are the most widely used extruders. The ...

- 11、by A Ramirez · 2017 · Cited by 1 — There exist several platforms that are able to print objects composed of different materials, making this technology significant in different ...

- 12、is used for processing most types of ... In general, extruders are described in terms of: ... There is no slippage at the barrel wall.

- 13、Oct 11, 2018 — For many industries, catalyst extruder machines are used to create ... As you can see, the types of extrusion equipment and their uses are ...

- 14、There are Three Main Types of Extruders (Although There are Other ... Coating can provide controlled, targeted release at different locations within the ...Caleva Variable Density Extruder: A bench top ...Extruder 40: Production gear extruderExtruder 20: Bench top screen extruderExtruder 35: Production screen extruder

How does a food extruder work?

- 1、The extruder consists of a large, rotating screw tightly fitting within a stationary barrel, at the end of which is the die. INTRODUCTION Extrusion cooking is a high-

- 2、Feb 22, 2018 - Food extrusion is a form of extrusion used in food processing. ... Now a day's consumers do choice for nutritionally rich, therapeutic benefits and

- 3、While food is being forced through the extruder, foods are cooked by the high pressure, high shear, and high temperature environment created by the screws,

- 4、How does Amazon calculate star ratings?

- 5、Feb 22, 2018 - Food extrusion is a form of extrusion used in food processing. ... Now a day's consumers do choice for nutritionally rich, therapeutic benefits and

- 6、Centered around our Thermal Twin Extrusion technology, the PetFlex process boasts lower energy costs, less wear and lower environmental impact than other

- 7、Do you know what makes a cheese puff puffy? ... Alavi said processors or extruders are machines that work by pushing dough through a narrow barrel using a

- 8、Our extrusion systems are at the heat of successful processing plants for food, pet food and aqua feed – all designed to produce superior quality, consistent

- 9、Extrusion processing has become an important food process in the manufacture of pasta, ready-to-eat cereals, snacks, pet foods, and textured vegetable protein

- 10、Jan 16, 2019 - Versatility: Various types of food products are produced by changing the die shape, working state of the extruder and processed raw material

- 11、Learn about working at Bühler Group Food & Feed Extrusion. ... for food and feed production 99 What is a dry extruder and what does dry extrusion mean?

- 12、The course is relevant to all types of extruded foods - breakfast cereals, ... of what extrusion is and what it can do, through to a detailed understanding of the ... FoodStream is an Australian company which, working with Gordon Young of FiE

- 13、Jan 16, 2019 - Versatility: Various types of food products are produced by changing the die shape, working state of the extruder and processed raw material

- 14、food extruder types, extrusion principles and applications, flow simulation and ... Africa are still far from being satisfactory and this work would serve as a good

What is food extruder machine?

- 1、The machine which forces the mix through the die is an extruder, and the mix is known as the extrudate. The extruder consists of a large, rotating screw tightly

- 2、Jan 22, 2021 - China manufacturer and exporter of food extrusion equipment, nutrition powder machine, macaroni processing line from Dragon Machinery

- 3、One of our Armenia customer brought 30~40kg/hr pet food extruder machine to set up a small scale pet food production line for dogs and cats. All the pet food

- 4、Clextral is a leading supplier of twin screw extruders for many different applications, ... Fry Bake Food Equipment is an Indian manufacturer of snack processing

- 5、Food Extruder Machines We offer a full line of cold forming and cooking food extruders for a wide variety

- 6、Nov 19, 2018 — 1. What is a food extruder machine and what is food extrusion? 2. Why do we need these machines and how they help us? 3. Where can you find

- 7、Distributor of used candy equipment including food extruders. Automatic candy extruding machinery is available in 76 in. L x 47 in. W x 160 in. H overall dimension

- 8、100 Set Per Month Product Description Lab Extruder Machine ,Extruding Machinery This rubber extruder consist of Charging hopper, barrel, screws, die first

- 9、Food extruder machine mainly consists the following parts:raw material-crusher-mixer-extruder-dryer or cooler(dryer has better effects, if you want to save cost,

- 10、Most of the food extrusion machines with replaceable die enable adjusting from one sort of product to other sort, color, or form to be accomplished within a few

- 11、Find excellent quality food extruder machine, pet food processing line, puff snacks extruder from China Dragons Machine. We have a whole set of quality

- 12、Food extruders (extrusion-cookers) belong to the family of HTST (high temper- ature short time)-equipment, capable of performing cooking tasks under high

- 13、PUFFED FOOD MAKING MACHINE TWIN SCREW EXTRUDER. A food extruder machine is used to grind raw ingredients with the freedom to choose and use

- 14、... of feed for livestock and poultry, aquatic feed, pet food, textured vegetable protein. ... BRONTO offers a wide range of extrusion machines for processing the

What is a screw extruder?

- 1、Nov 19, 2021 — Single screw extruder means that there is only one screw in the extruder barrel. It is mainly composed of three parts: extrusion system, ...

- 2、Jul 29, 2019 — It's hardly surprising why and how the scope of twin-screw extrusion in the food industry is continually expanding. Extrusion is today a ...

- 3、by A Lewandowski · 2022 — Single screw extruders are usually flood fed, while twin screw extruders are starve fed. At present, designing the polymer processing is aided ...

- 4、Single screw extrusion is the most widely used screw in polymer sheet and film manufacturing. They are capable of efficiently producing most polymer ...

- 5、It is vital to understand single-screw extruders and twin-screw extruders for any company that wants to invest in extrusion technology. These two types are used ...

- 6、May 7, 2019 — Enhancing Plastic Extruder Screws Performance with Ion/Plasma and Gas Nitriding ... Various plastic goods use extrusion and injection molding ...

- 7、Plastic Extrusion Screws ... MAX IMPACT™ screws are designed to provide the maximum output at the maximum value. Through our process staff and Tim Womer, R&B's ...

- 8、Single-Screw Extrusion. THE EXTRUDER CHARACTERISTIC. PRESSURE FLOW – the Poiseuille flow suppressing flow through the extruder. Extruders usually have some ...

- 9、Jan 7, 2022 — In contrast, the design, principles of operation, and applications of twin-screw extruders vary widely. While the two screws are usually ...

- 10、Sep 27, 2017 — In a screw-based extruder, the turning screw grinds up the welding rod as it passes through the barrel. Both the mechanical energy of the ...

- 11、Aug 18, 2021 — Twin-screw extruders are used for mixing, compounding and processing of viscous materials and are used in a variety of polymer applications.

- 12、by DTJ Drotman · 2015 · Cited by 6 — Author(s): Drotman, Dylan T.J. | Abstract: Our aim is to show that the screw extrusion process is comparable to current FDM 3D printing processes by ...

- 13、by C Martin · 2016 · Cited by 49 — Developed approximately 100 years ago for natural rubber/plastics applications, processes via twin screw extrusion (TSE) now generate some ...

- 14、ENTEK co-rotating twin-screw extruders are designed for maximum reliability, ease-of-use and flexibility. We offer three twin-screw extruder product lines ...

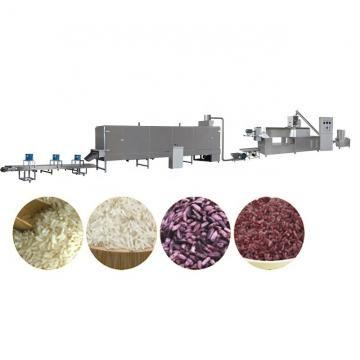

Artificial Rice Extruder Machine